Recently team Denim Focus visited Crown Wears (Pvt.) Ltd. factory and observed state-of-the-art sustainable washing facilities with the latest technology addition. We talked with Mr. Shovon Islam, Managing Director, Crown Wears (Pvt.) Ltd. Key findings are mentioned below-

Recently team Denim Focus visited Crown Wears (Pvt.) Ltd. factory and observed state-of-the-art sustainable washing facilities with the latest technology addition. We talked with Mr. Shovon Islam, Managing Director, Crown Wears (Pvt.) Ltd. Key findings are mentioned below-

About Crown Wears (Pvt.) Ltd:

Crown Wash Facilities, a concern of the Sparrow Group, started its journey only four years ago. The factory is trying to develop more & more environment-friendly & innovative garment washing & dyeing effects here. The factory washes around 120000 garments daily, dying around 40000, and denim washing around 20000-25000 pieces of garments. And this is a 100% sustainable & nature-based garments & washing plant. 100% water of this plant passes through the Effluent Treatment plant (ETP). We have taken on a project to install another Effluent Treatment plant (ETP) and hope to complete it by 2025. Not only will we reprocess 100% water from this plant, but also, we will reuse that. Bangladesh is the number one denim manufacturing country in this country. I believe sustainable denim has a huge market opportunity. If we can provide sustainable denim to our buyers, the demand for denim from Bangladesh will increase. I encourage others to come

Technologies being used in Crown Wears factory:

Technologies being used in Crown Wears factory:

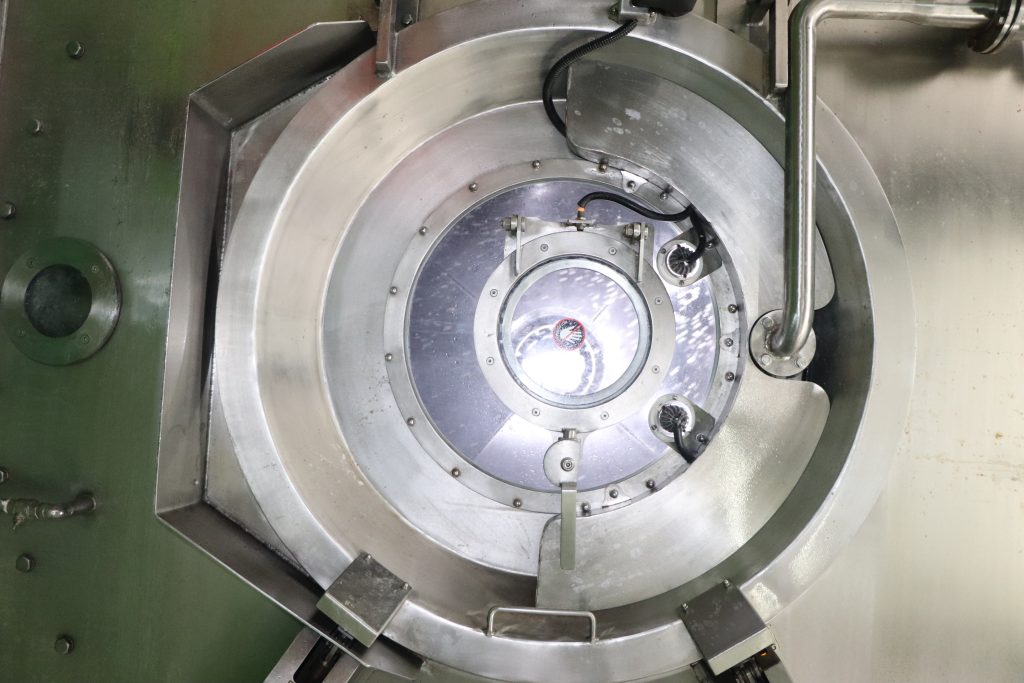

Recently Crown Wears (Pvt.) Ltd. has installed a sustainable wash technology named Xeros. This Xeros technology was built in the research park of the UK. Ramsons Company has implemented this technology recently in India. Now, Crown Wash Facilities has installed this Xeros technology. Generally, in denim wash, we used to use pumice stones to introduce wash effects. In Xeros technology, polymer bubbles are used instead of pumice stones to bring the wash effects. In this technology during the wash, polymer bubbles come out of the machine & Again after the washing process the polymer bubbles are soaked in the washing machine. This sustainable technology reduces around 70% of water use, 50% of chemical use, and 50% of wash time and increases the load by 20%. But provides the same or sometimes better wash effect and saves the environment.

The recent development of Crown Wears (Pvt.) in the dyeing process:

Besides regular denim washing technologies, Crown wash Facilities has a strong R & D section that constantly introduces new & innovative wash effects. Recently, we have been using a new type of Dye named “Tea Dye” for “M&S Company.” This dye is produced from the Tea that we drink. The advantage of this dye is that it is natural & it does not require any chemicals. As a result, it is good for the environment & also we can directly release the dyeing water into the environment without any special treatment / ETP. The look and hand feel of the garment are also good. We have already dyed around 200000 pieces garments with it & we have huge order. Currently, we are importing this dye from Europe & Sri Lanka. We hope that soon this dye will be available in India & Bangladesh and the demand for this dye will increase. Another dye that I would like to draw attention to is Mineral Dye. This is also a natural dye, and its Environment Impact Analysis Management Score is only 16, while in the case of other washes the score is around 70-80. We have prepared denim using this wash effect for one of the top women’s brands in USA.