Denim Focus Industry Correspondent

Sparrow Apparels, a company jointly owned by Sparrow and ACL (India) has become an example to follow in the context of doing flawless business amid the adversities all around. Hitting shipment deadliness with surprisingly high production efficiency along with protecting resources, the environment and its people, Sparrow Apparels has been able to make the most out of its business with high standards. They are literally a benchmark in industry best practices and relentlessly working towards further improvements. Denim Focus is delighted to feature such a factory to inspire our readers. Sparrow was founded in 1984 by Professor Dr. Mahzharul Islam. The Group now has multiple manufacturing units with over 11,000 people and revenue reaching 150+ Million US dollars (1500 Core Bangladesh Taka). Sparrow currently produces the highest quality products for the World’s renowned retailers such as GAP, Banana Republic, Ann Taylor, Talbots, Loft, American Eagle, Kohls, Old Navy, Bass Pro, Mango and many others.

Sparrow was founded in 1984 by Professor Dr. Mahzharul Islam. The Group now has multiple manufacturing units with over 11,000 people and revenue reaching 150+ Million US dollars (1500 Core Bangladesh Taka). Sparrow currently produces the highest quality products for the World’s renowned retailers such as GAP, Banana Republic, Ann Taylor, Talbots, Loft, American Eagle, Kohls, Old Navy, Bass Pro, Mango and many others.

Automation and Resource Optimization

Cluster Lean Practice in Sewing Floor

The sewing section adopts the cluster lean manufacturing method, where the multi-skilled sewing line operators work in a team unlike most of garment manufacturing factories where the production lines are linear and progressive. The main feature of the cluster sewing method is its high efficiency and quality control. There are two separate sections in every sewing lines: The component joining team and the Assembling team. In the component joining the team two groups of operators start joining the front part and the back part simultaneously and deliver the complete front part and back part of the garment to the assembling section whose responsibility is to join both parts and make a complete garment. Quality control operators are staged after every major manufacturing section like after the front part joining section, back part joining section and any other complex or high-risk section enabling flawless production. Another important feature of the cluster system is its ability to quickly change over from style to style. Every line is equipped with one or two multi-skilled operators who can be easily floated within the line as per production requirements. Every line also includes one trained fire operator and health service provider so that any emergency need can also be delivered within the cluster. All these amazing features of the sewing line at sparrow Apparels allow them to ensure very high product quality and productivity.

The sewing section adopts the cluster lean manufacturing method, where the multi-skilled sewing line operators work in a team unlike most of garment manufacturing factories where the production lines are linear and progressive. The main feature of the cluster sewing method is its high efficiency and quality control. There are two separate sections in every sewing lines: The component joining team and the Assembling team. In the component joining the team two groups of operators start joining the front part and the back part simultaneously and deliver the complete front part and back part of the garment to the assembling section whose responsibility is to join both parts and make a complete garment. Quality control operators are staged after every major manufacturing section like after the front part joining section, back part joining section and any other complex or high-risk section enabling flawless production. Another important feature of the cluster system is its ability to quickly change over from style to style. Every line is equipped with one or two multi-skilled operators who can be easily floated within the line as per production requirements. Every line also includes one trained fire operator and health service provider so that any emergency need can also be delivered within the cluster. All these amazing features of the sewing line at sparrow Apparels allow them to ensure very high product quality and productivity.

The Production Efficiency

Sparrow Apparel is an excellent example of how the complete system can be integrated to reach a high production efficiency. Starting from the fabric store to the cartooning department every production section within is connected with a traffic light system so that everyone is readily aware of the production and inventory status. In the event of a shortage of body parts in the sewing section, the respective operator just switches on the traffic light system which sends a signal to the respective cutting table. The cutting operators take immediate steps to send the body parts. Similarly, in the cutting section when there is a shortage of fabrics, the respective cutting operator just switches on the traffic light system and it sends a signal to the fabric store, who send the desired fabric immediately to the cutting section. Their emphasis on preproduction is something unparalleled enabling them to reach a 99% cut-to-ship ratio which is something above the benchmark. Sparrow is a woven factory and the styles of the garments are often highly valued and fashionable designs with washes, prints and special processes. With their intelligent and integrated production system, they are able to ensure high margins even from small orders and complex designs which is not common in most of the garment factories in our country.

Digital Warehouse

Sparrow Apparel has a digitized warehouse system where all data related to fabrics are fed into the ERP system according to shade, pattern, and shrinkage. By scanning the Barcode, fabric storage information can be known immediately. And this info can be seen from every department even from their India office. The warehouse is also equipped with a humidification system that enables fabrics to be free from any faults from microorganisms.

Modern CAD-CAM Section

Automation has been playing a great role in this section also. All digital CAD CAM machine with the latest software helps them to make 100% accurate and waste minimized pattern and marker making. Modern Pattern cutter templates can be used for making several pattern without any damage.

Advancement in Washing

Advancement in Washing

Linear programming system, on loading dryer system added new dimension to washing section compared to conventional washing. Different type of special processes like tie-dye, rope dye, reactive pigment dye, and hydrophobic (water-repellent) wash can be done here with using less water and less energy.

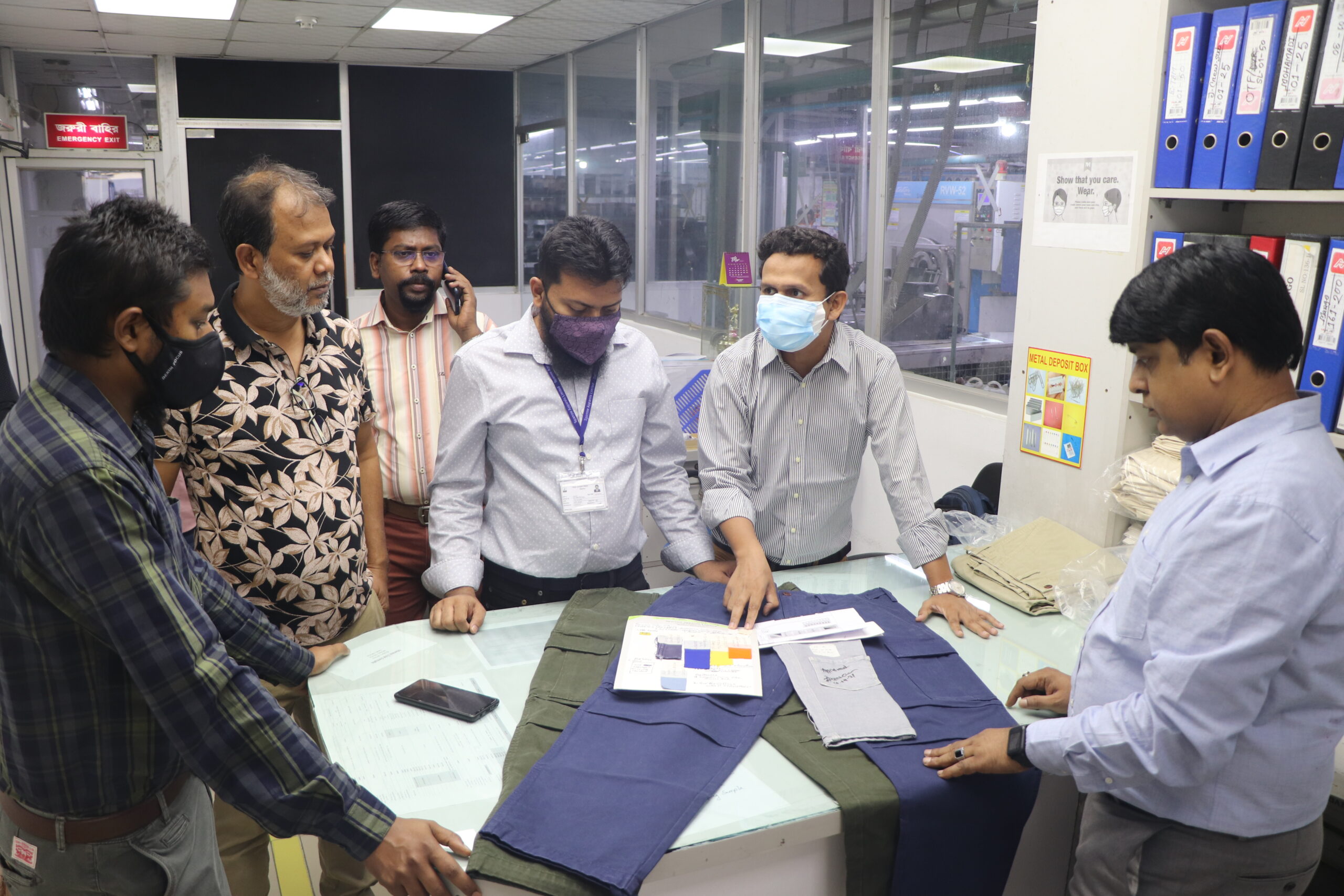

R&D

Well-equipped R&D department with modern lab facilities of Sparrow Apparels can easily satisfy customer demands. The R&D department have a modern and expensive data color machine that can easily open QFX file for accurate color identification.

Well-equipped R&D department with modern lab facilities of Sparrow Apparels can easily satisfy customer demands. The R&D department have a modern and expensive data color machine that can easily open QFX file for accurate color identification.

In the Lab, all kinds of tests can be run without any disruption as the lab is equipped with different digital and latest machines like Martindale Abrasion Tester, Tear Testing Machine, PH meter, Shaker machine, Spectrophotometer for identifying recipes, the latest software for calculating accurate measurement and many more.

Sustainability & Green Initiatives

Uses of sustainable raw materials, maximising energy efficiency, water efficiency, and proper waste management are their core practices to achieve sustainable goals. Apart from these Sparrow Group strives to conduct sustainable manufacturing and has implemented many green programs. Like,

- Plant trees around the factory complex.

- Plant 1000 small plants across each floor.

- 20% reduction in Green House Gases by Dec 2022 through control of Generator & Boiler emissions by installing air quality control devices.

- Implemented Environmental Management System to review, evaluate and improve environmental performance through constant monitoring.

- Installed Solar Panels to provide power to warehouses.

Safety & Security

Fire Safety

Sparrow Group recognizes the safety risks associated with working with various types of machinery and thus ensures the full safety of all their employees. As per the Govt. rules, 18% of workers are trained for fire safety. 100% of workers have awareness training. Sparrow Group has Achieved 100% Completion of Structural, Fire and Electrical Safety Certification in accordance with Accord and Alliance.

Key areas:

- Fire-safe building layout.

- Monthly fire drills to train workers to evacuate safely.

- Special fire trainees on each floor lead fire evacuation and are trained with a fire house.

- Machine emergency lights to signal if the machine is not functioning correctly.

- Trained professional guards around the factory perimeter to protect employees.

- Earthquake-protected building, along with building checks every 6 months.

- Labour Link Project (Application to survey factory conditions) with the highest rating in all 3 stages.

Sparrow Apparel has more than 1122 smoke detectors, 449 fire extinguishers, and a Reserve water capacity of 1 lakh 96 thousand gallons, 52 centre nozzle hose pipe with an automatic system.

Workers’ Health & Safety

Sparrow ensures the safety of their employees. They make sure any health or safety concerns are mitigated, so employees can work without worry. 2 MBBS Doctors, 3 certified Medical assistants, and 2 Nurses are serving to resolve the health issues of workers. They have an agreement with one Hospital and a dialogue running with another hospital. Medicines are provided free to all workers.

Sparrow ensures the safety of their employees. They make sure any health or safety concerns are mitigated, so employees can work without worry. 2 MBBS Doctors, 3 certified Medical assistants, and 2 Nurses are serving to resolve the health issues of workers. They have an agreement with one Hospital and a dialogue running with another hospital. Medicines are provided free to all workers.

Measures were taken during Corona

According to rules by Government, BGMEA, ILO and maintaining the WHO standard they have been taking all precautionary steps to fight against CORONA.

According to rules by Government, BGMEA, ILO and maintaining the WHO standard they have been taking all precautionary steps to fight against CORONA.

They said that employee health is their number one priority. After the government resumed factory operations, they have taken measures to mitigate transmission and ensure the safety of their employees:

- Sanitation booths are placed around the factory.

- Factory premises (especially touch surfaces) are sanitized and cleaned frequently throughout the day.

- Full body sanitation booth before entry into the factory.

- Daily temperature checks before entry.

- Social distancing and hand wash signs were placed across the factory.

- Appropriate medicine is provided to doctors such as Remdesivir.

- Quarantine rooms were created for workers.

- Masks are Mandatory.

Corporate Social Responsibility Practices

Sparrow Group strives to maintain its CSR by implementing programs to create a just and equitable working environment for employees. Many of these programs are in collaboration with our clients and constitute as globally recognized programs. They have achieved Better work Score: 98%, GSV- 100%, HIGG Index- 84%, Accord- 96%, Alliance- 100% along with GOTS and GRS Certifications.

Sparrow Group strives to maintain its CSR by implementing programs to create a just and equitable working environment for employees. Many of these programs are in collaboration with our clients and constitute as globally recognized programs. They have achieved Better work Score: 98%, GSV- 100%, HIGG Index- 84%, Accord- 96%, Alliance- 100% along with GOTS and GRS Certifications.

Current programs

Mark & Start:

Program in collaboration with Marks & Spencer and CRP with the objective of training and employing disabled people in the Garments sector.

P.A.C.E. (Personal Advancement and Career Enhancement):

Program in collaboration with GAP, created to support women in the global apparel industry. The program provides women with foundational life skills, technical training and support that will help them advance in the workplace and in their personal lives.

Mothers@Work

Program in collaboration with BetterWork which aims to uphold maternal rights, and provide breastfeeding and child-caring services in the Garments Factory

HER project:

Program in collaboration with Ann Taylor to empower women in the Garments industry through family planning, reproductive health knowledge, nutrition and financial literacy training.

Sobola:

This Program is in cooperation with MANGO for increasing worker empowerment and supervisory skills.

TT & TB vaccination:

Program in collaboration with Bhaluka Upazali Health Complex which allows garment workers to receive TT (Tetanus Toxoid) Vaccination and TB (Tuberculosis) free of cost.

Other projects are VSCF for health and safety; WPT, WPC, SLCP, WEP, and WWCP Pilot. They also provide Maternity benefits with full payment; 2 times breastfeeding; childcare; nutrition food, Krimi medicine etc. Sparrow Apparels Ltd is now the role model for practising CSR recognized by the Government, the Ministry of Health, ILO and Better work.

Welfare Program

Sparrow Group values togetherness and strives to create a community of individuals who enjoy working together and bring out the best of one another through:

- Hosting annual picnics which include a special venue, local musical artists and food for a group celebration.

- Frequent social gatherings by the department for team bonding.

- Planted 1000 trees across the workspace for worker relaxation and mental health.

The unparalleled features of Sparrow Apparels have made them a factory with out of the box solutions of the common prevailing problems associated with the contemporary garment manufacturing business. It is an inspiration, example and guide for the other factories who are working towards achieving more profitability, sustainability and business growth.

Sparrow’s adherence to innovation, standardization and resiliency can be portrayed from its Managing Director’s quote that says –

“In this competitive business market, if we want to develop our industry we must follow standard operating procedures for process and resource optimization. Cost is rising but buyer price remains almost the same. In this case, Preproduction stage is the most important part. 99% cut to ship is the main criteria to achieve the goal”- Shovon Islam Shawn, Managing Director, Sparrow Group of Industries.

“In this competitive business market, if we want to develop our industry we must follow standard operating procedures for process and resource optimization. Cost is rising but buyer price remains almost the same. In this case, Preproduction stage is the most important part. 99% cut to ship is the main criteria to achieve the goal”- Shovon Islam Shawn, Managing Director, Sparrow Group of Industries.

Watch Industry Best Practices of Sparrow Apparels ltd-