Halima Tus Sadia

The second-largest popular wearing after t-shirt is denim. It is popular among people of any age. Even fashion without denim is incomplete nowadays. It is notably using apparel globally for its consolation and durability. Denim is a twill fabric, generally composed of cotton fiber, made with colored warp yarn and white weft yarn. However, the question that may arise in our minds is whether we can manufacture denim solely from cotton fiber. In this article, we will learn the answer to the question of which fibers can be used to make denim fabric besides cotton.

Wool:

Woolen denim fabrics are advantageous due to their hygroscopic and porous structure, soft feeling, and high resilience. Furthermore, it enhances warmth without adding bulk to the fabric allowing for a higher level of comfort. It feels drier on the skin when wet and more comfortable than 100% cotton. To manufacture wool denim, wool/cotton blended yarns are used. The Woolmark Company has collaborated with development partners to create a wool/cotton denim blend which uses exactly the same warp yarn as traditional denim, but replaces some, or all, of the weft yarns with machine-washable wool. Wool denim fabric can be finished in the same way as traditional denim, so style is not compromised. With that all of the natural benefits associated with wool can thus be enjoyed.

Woolen denim fabrics are advantageous due to their hygroscopic and porous structure, soft feeling, and high resilience. Furthermore, it enhances warmth without adding bulk to the fabric allowing for a higher level of comfort. It feels drier on the skin when wet and more comfortable than 100% cotton. To manufacture wool denim, wool/cotton blended yarns are used. The Woolmark Company has collaborated with development partners to create a wool/cotton denim blend which uses exactly the same warp yarn as traditional denim, but replaces some, or all, of the weft yarns with machine-washable wool. Wool denim fabric can be finished in the same way as traditional denim, so style is not compromised. With that all of the natural benefits associated with wool can thus be enjoyed.

Silk:

Silk fabric is popular due to its excellent properties such as softness, suppleness, strength, lightweight, sheerness, wrinkle resistance, elasticity and long-lasting pliability. So manufacturing denim fabrics from silk fiber can add a new dimension for not only denim but also silk. Again, silk denim fabric can be lightweight as silk is fine and strong. Silk denim fabrics in 14 combinations in weight range of 100 to 300 gsm are developed with 100% mulberry silk, 100% eri silk and combination with cotton and linen as blend fabrics. The silk denim garments are soft to touch, light in weight, comfortable to wear in all the seasons, blended with the luxury and smooth feel. The eri silk has thermal properties nearly equivalent to wool which makes 100% eri silk denim garments apt for winter. The silk/cotton and silk/linen blend denim fabrics are more cost-effective without losing their comfort and silky appearance. These new products will add a new dimension to the denim and fashion world in general and silk and silk blended products, in particular, and open up a whole new range of fabric to the younger generation.

Linen:

Linen is a cellulosic bast fiber. It actually comes from flax fibers and fabric made of linen is one of the oldest fabric used around the world. Soft and comfortable denim fabric can be developed from linen blended with cotton. Linen blend denim (58% cotton & 42% linen) is developed by Levi’s which is a sustainable initiative. The innovation offers significant water savings.

Kapok:

The kapok fiber is derived from the kapok tree. It is called cotton silk for its excellent properties buttery softness like silk. As kapok is known for its many naturally occurring benefits and sustainable attributes, it can be blended with cotton to achieve a softer hand feel while keeping an authentic rigid look. It has also been useful in spring/summer collections due to its moisture wicking and quick drying ability. Its antibacterial properties also help mitigate odor and with denim professionals alike that refuse to wash their jeans, this is a key aspect the kapok fiber can help with.

Jute:

Jute is a bast fiber obtained from the bark of the jute plant. Jute fiber blended with cotton can be used for denim production. The production of jute blend denim can be cost effective than 100% cotton yarn. At the same time, it will reduce the dependency on cotton. With that it can be eco-friendly denim product. To produce jute denim fabric, jute fiber is processed with a variety of chemicals and softened to near cotton quality. Then they are blended together in a process what is called ‘cotton processing system’.

Hemp:

Hemp is one of the strongest natural fibers. It feels nice and can be worn directly on the skin, has good anti-bacterial and UV-resistant properties and is 100% biodegradable. Hemp always feels cool due to it contains little air and has relatively little insulating properties. Hemp has a high moisture-absorbing capacity and also easily releases the moisture to the outside. Hemp is used for producing denim blended with cotton which increases the quality of the denim fabric. This cotton blended hemp is used for making jeans, jackets, skirts etc.

Hemp is one of the strongest natural fibers. It feels nice and can be worn directly on the skin, has good anti-bacterial and UV-resistant properties and is 100% biodegradable. Hemp always feels cool due to it contains little air and has relatively little insulating properties. Hemp has a high moisture-absorbing capacity and also easily releases the moisture to the outside. Hemp is used for producing denim blended with cotton which increases the quality of the denim fabric. This cotton blended hemp is used for making jeans, jackets, skirts etc.

Bamboo:

Bamboo fabric has a good reputation from the benefit to both human and earth in the clothing industry. Bamboo fabric has a soft touch and a stronger fabric. Due the fabric’s structure, the fabric is very breathable to stay cool in the summer and warmer in the winter. Also, it can absorb 3-4 times more water than the traditional cotton fabric without sticking to your skin. It is very good for manufacturing denim jeans. Bamboo denims are super soft with just the perfect amount of stretch that offers sublime comfort, whatever the challenge. It is incredibly absorbent so it keeps wearer feeling fresh and dry even when they sweat. So it doesn’t get smelly and can wear longer between washes.

Bamboo fabric has a good reputation from the benefit to both human and earth in the clothing industry. Bamboo fabric has a soft touch and a stronger fabric. Due the fabric’s structure, the fabric is very breathable to stay cool in the summer and warmer in the winter. Also, it can absorb 3-4 times more water than the traditional cotton fabric without sticking to your skin. It is very good for manufacturing denim jeans. Bamboo denims are super soft with just the perfect amount of stretch that offers sublime comfort, whatever the challenge. It is incredibly absorbent so it keeps wearer feeling fresh and dry even when they sweat. So it doesn’t get smelly and can wear longer between washes.

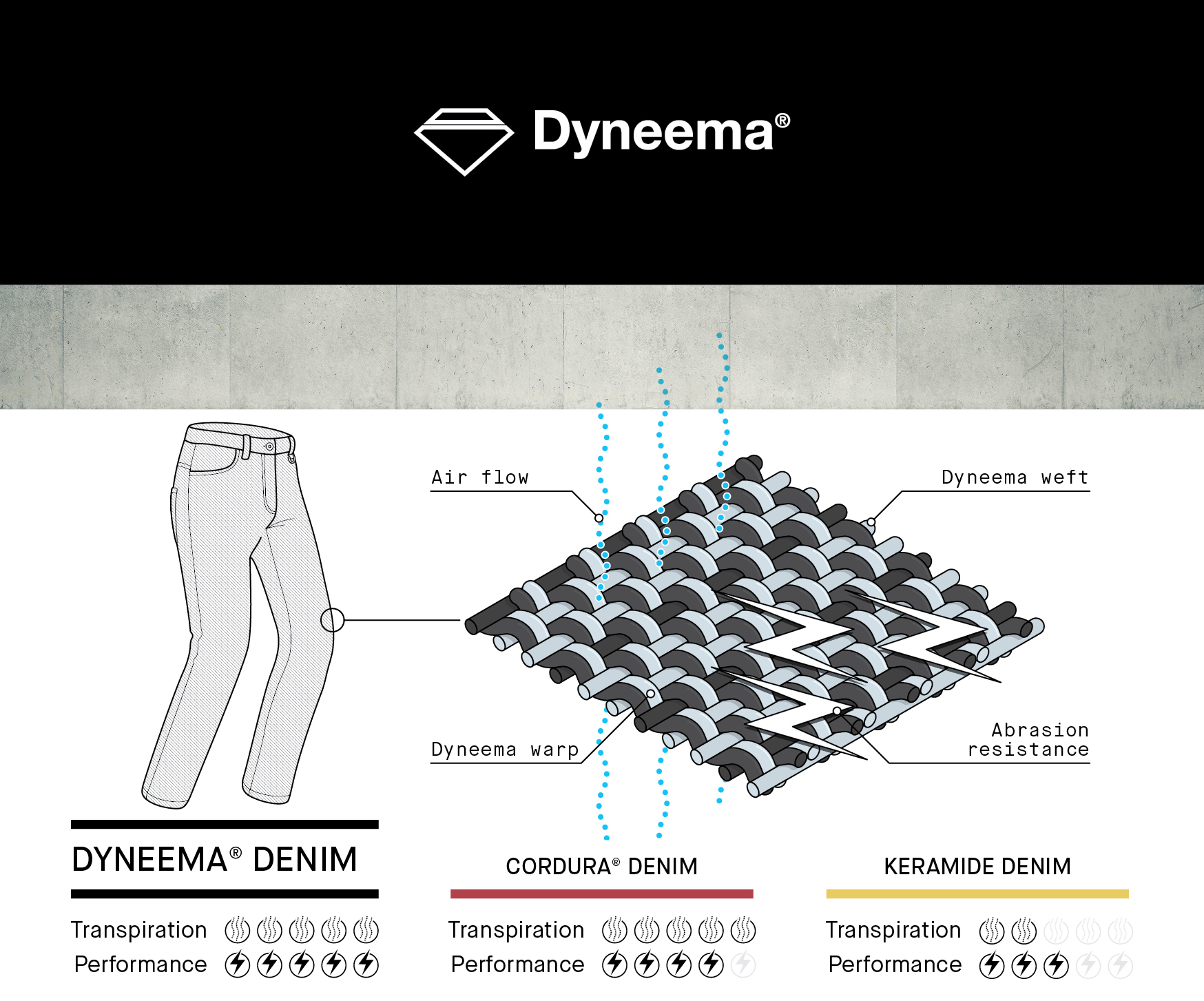

Cordura:

Denim made of cordura fiber is intended last longer than traditional 100% cotton denim. It’s engineered with an intimate blend of military-grade INVISTA T420 nylon 6,6 staple fiber and cotton for an authentic denim look, feel and comfort as well as enhanced abrasion resistance. CORDURA® Denims are stronger than conventional cotton denims and retain their strength even after regular wear and tear, but they feel like 100% cotton denim. Aside from the high-performance properties of denim fabrics produced with Cordura®, the color performance is good as it does not fade for a long time.

Denim made of cordura fiber is intended last longer than traditional 100% cotton denim. It’s engineered with an intimate blend of military-grade INVISTA T420 nylon 6,6 staple fiber and cotton for an authentic denim look, feel and comfort as well as enhanced abrasion resistance. CORDURA® Denims are stronger than conventional cotton denims and retain their strength even after regular wear and tear, but they feel like 100% cotton denim. Aside from the high-performance properties of denim fabrics produced with Cordura®, the color performance is good as it does not fade for a long time.

Emana:

Emana® fiber is used to create denim fabrics that are beneficial to the body, and these fabrics stand out with functional features that go beyond fashion. Emana® fibers are activated by the body’s natural heat. Fibers absorb body heat and convert it to far infrared rays (FIR). These rays reduce cellulite in the body and give the skin a smoother, younger appearance. Solvay’s intelligent yarn based on polyamide 6.6 embedded with bioactive minerals is used in the Emana® technology. Denim jeans with Emana® fibers have a very soft and smooth feel to them. Infrared rays improve blood circulation throughout the body. Skin roughness and the appearance of orange peel are reduced. Independent laboratories and institutes have approved and patented Emana technology; it is Oeko-Tex® certified, which means it is not harmful to human health and is skin compatible.

Dyneema:

Dyneema® is Ultra High Molecular Weight Polyethylene (UHMWPE). As the world’s strongest fiber™, Dyneema® offers maximum strength combined with minimum weight. Fifteen times stronger than steel and up to 40% stronger than aramid fibers. Lighter than water, Dyneema® is water repellant, highly resistant to UV light and chemicals, and highly thermo-conductive. Dyneema® Denim is a fabric that is increasingly being used in high-performance sports ranging from mountain climbing to motorcycling. Depending on the technology used, Dyneema® Denim can provide unrivaled protection for extreme sports applications as well as extra strength and durability for everyday wear. Whatever the application, the lightweight fabric remains soft, comfortable, and cool to the touch.

Dyneema® is Ultra High Molecular Weight Polyethylene (UHMWPE). As the world’s strongest fiber™, Dyneema® offers maximum strength combined with minimum weight. Fifteen times stronger than steel and up to 40% stronger than aramid fibers. Lighter than water, Dyneema® is water repellant, highly resistant to UV light and chemicals, and highly thermo-conductive. Dyneema® Denim is a fabric that is increasingly being used in high-performance sports ranging from mountain climbing to motorcycling. Depending on the technology used, Dyneema® Denim can provide unrivaled protection for extreme sports applications as well as extra strength and durability for everyday wear. Whatever the application, the lightweight fabric remains soft, comfortable, and cool to the touch.