Itema is a leading global provider of advanced weaving solutions, including best-in-class weaving machines, spare parts, and integrated services. The Company is the only manufacturer in the world to provide the top three weft insertion technologies: rapier, airjet, and projectile, with a comprehensive product portfolio and a commitment to continuous innovation and technological advancement of its weaving machines. Weaving machines with the well-known brand Itema leaves assembly lines in Italy, Switzerland, and China every day. Itema has a tradition of almost 200 years, with an installed base of over 300,000 weaving machines. A global presence in more than 100 countries ensures fast and reliable service. Itema participated in DTG 2023. Ugo Ghilardi, CEO of Itema Group & Ferdinando De Micheli, Group Sales Director of Itema Group, visited Bangladesh during the exhibition. Team Denim Focus spoke with Ferdinando De Micheli regarding Itema’s recent product developments and business scenario. Key discussion points are mentioned for our readers-

Latest developments and business situation:

The year 2022 was full of much news for Itema Group. From the point of view of sales volumes, the results testify that the Itema technology and its added value are widely recognized today by the market. We renewed many meaningful partnerships worldwide, but what made a real difference last year was the opportunity to penetrate new markets and gain many new Customers, especially in some strategic textile districts. We are delighted with the orders collected over the last year and aim to do even better Itema; we are tirelessly working to reduce the footprint of our production processes, as well as the impact of our technology while finding new ways to make our Customers’ life easier by working intensively on the development and integration of digital technologies. In particular, tools for monitoring, controlling, and thus further improving production plays a central role in pursuing this goal, thanks to intelligent troubleshooting systems. You will find out more about this at ITMA Milan 2023.

Observation on the textile industry of Bangladesh?

Despite garments being a significant industry in Bangladesh, the enormous amount of fabric required is still imported from other countries. In this landscape, the future development of the weaving industry represents one of the main potential sectors for developing the Bangladeshi textile industry.

Itema positions itself as a reliable partner – and not only a simple supplier – for textile companies, providing advanced weaving machines, real-time after-sales service, highly professional training for the weavers, and integrated textile consultancy. We consider Bangladesh as one of our important markets, and we have been here for a long time.

Response at DTG 2023 exhibition in Dhaka:

We are very much glad to meet our customer with so many queries. DTG is, for Itema, the perfect stage to allow Bangladeshi weavers to experience first-hand the weaving solutions provided by the company, which are renowned worldwide for their superior textile mastery, eco-efficiency, and ease of use.

On the show, Itema showcased its denim-dedicated rapier weaving machine; on display, the weaving machine is courtesy of Universal Denims, Bangladesh, which selected Itema as a trusted technological partner to produce its premium denim fabrics. The machine comes from the bulk order of 99 Itema rapier R9500-2denim that Universal Denims recently installed in its mill.

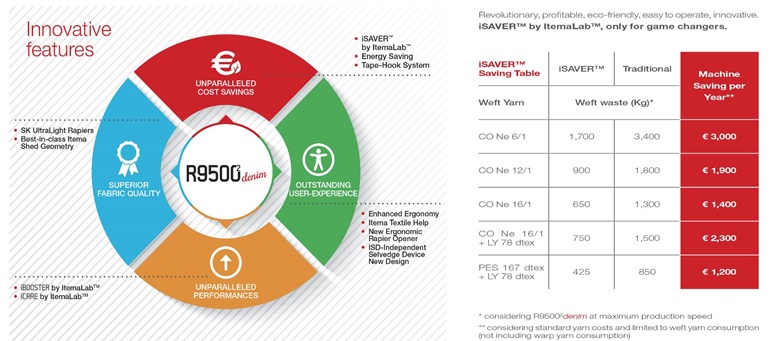

R9500-2denim the real iSAVER:

The R9500-2denim at DTG 2023 was equipped with iSAVER®, the one-of-a-kind mechatronic device capable of eliminating the waste selvage on the left-hand side of the fabric, thus leading to significant costs savings and reducing waste, contributing to a sustainable denim weaving. iSAVER® is already successfully installed in many leading denim mills worldwide and represents a real attractive added value for Bangladeshi weavers that deal daily with Western brands, which are increasingly looking at green and sustainable production chain for the fabrics they purchase.

Services ensure for Bangladeshi customers:

To always be close to our Customers and to allow them to get the most out of their looms, we have a dedicated, fully trained professional service based in Bangladesh. Moreover, our regional customers can rely on our local partner for everything that concerns commercial, after-sales, and spare parts services. Texcotech is our local partner in Bangladesh, and our India team frequently visits the customer for quick service and feedback.

Feedback received from worldwide customers:

ISKO™ purchased new state-of-the-art technology in weaving machines, ISKO pushes the envelope of technological performance and sustainability, making further progress in product and process efficiency. “In these innovations, we saw a great potential to advance our sustainable strategy even more, and in Itema, the ideal partner with which to share a determined, long-term approach,” explains Fatih Konukoğlu, ISKO CEO. “Both our companies are leaders in their respective fields, fabric innovation, and weaving technology, and this collaboration creates a common ground of excellence that will benefit the whole denim world.”

At Sharabati Denim, the R9500-2denim and iSAVER® performances were very satisfying– the best in their category – and led in 2021 to a repeat order for the Egyptian and the Turkish plant for more than 180 machines. Just consider that – as reported by the company – the iSAVER® equipped on the weaving machines in production ensures Sharabati Denim a yarn saving that ranges from 650 Kg to 900 Kg per machine per year. In 2022, Sharabati Denim implemented an expansion project to increase its production capacity significantly. The weaving partner selected to provide 200 weaving machines for the Egyptian mill is Itema and, once again, its rapier R9500-2denim with iSAVER®. With this last order, Sharabati Denim owns a fleet of more than 400 Itema rapier R9500-2denim, thus achieving outstanding performance, sustainability, and technological prowess.

Universal Denims Limited selected Itema as its trusted technological partner for producing premium denim fabrics. Itema installed the bulk order of 99 Itema rapier R9500-2denim and provided one Itema rapier R9500-2denim to showcase at DTG 2023. Atiqul Alam Chowdhury, Managing Director of Universal Denims Limited, commented: “Universal Denims Limited works on sustainable manufacturing processes, innovation, carbon-footprint reduction, and utility efficiency. The yarns and chemicals used in our plants come from organic, sustainable sources, we adopt an ozone finishing process that reduces environmental impact, and fabric stretching is realized with an aero finish to increase durability. Moreover, our state-of-the-art effluent treatment plant saves 172 million liters of natural water annually, equipped with e-labs that make our factory extremely eco-friendly. Itema’s technology further helps us reduce the footprint of our activities while not compromising in terms of weaving efficiency and fabric quality – we are therefore delighted to further enhance our partnership by having one of our Itema R9500-2denim rapier weaving machines on display at DTG”.

Special preparation and developments for ITMA 2023:

The 2023 edition is particularly relevant since the most important international textile machinery exhibition will return to our home country. Over the last four years, as Itema, we worked hard to prepare to welcome our customers worldwide.

What I can disclose for the moment is that the selling process for Itema is just one step of the machine’s lifecycle. Therefore, we aim to give customers vast opportunities to get the most out of their weaving machines. More details will follow, so stay tuned!