Benefits:

Benefits:

Reduced number of vats

The design of the dyeing vat (type DV) allows you to attain a darker indigo shade with only eight boxes. Due to the shorter dye section, the total volume of the dye bath is drastically reduced.

Less chemicals

The indigo circulation system with high flow rates and low speed combined with the closed design of dyeing vats allow savings of up to 20% of hydro and caustic soda.

High weaving efficiency

Thanks to perfect tension control during the entire process preserving the yarn elasticity.

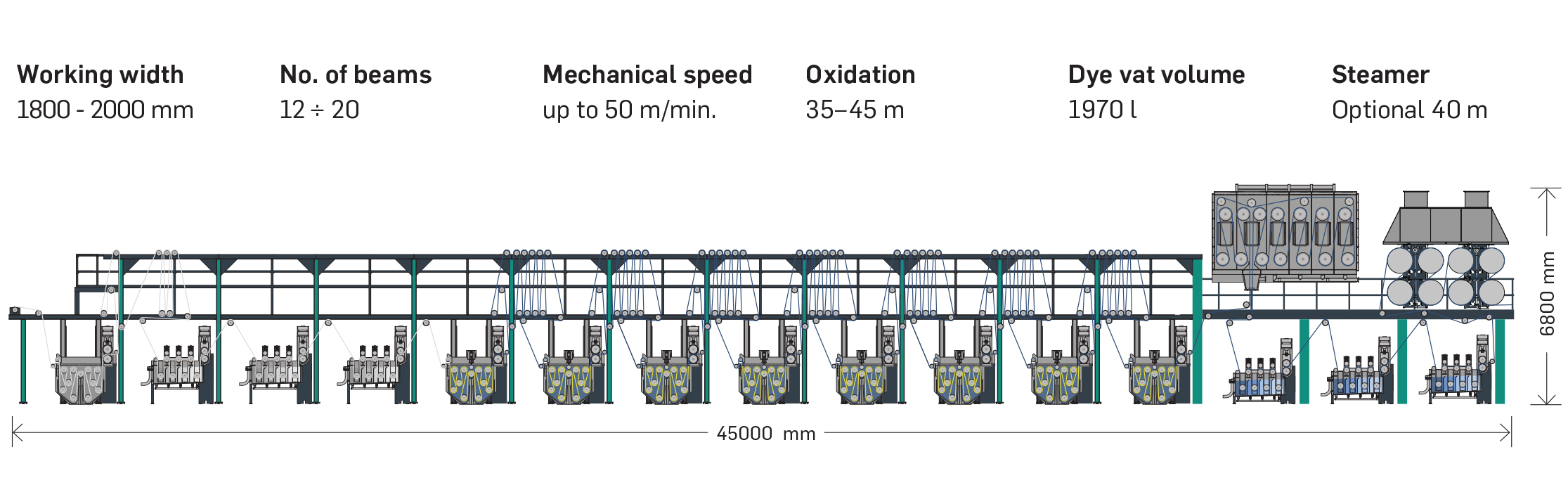

Technical data

Double Vario

– Longest Dwelling in slasher technology (11.2m)

-Integrated roller- lifting device, easier yarn reparigin, better cleaning and maintenance, less preparation time.

– Perfect bath circulation with cross-flow system for uniform dyeing result

Quick Oxidation

– Increased dyestuff pick-up with hot airflow

– 30% reduction in oxidation length

– Less yarn waste and better tone uniformity of the warp sheet

Double Head System

In the case of lightweight denim (<200 g/m in warp), the double head system enables productivity to be doubled. With this unique feature, KARL MAYER is able to guarantee a perfect and uniform dye process with a yarn density of up to 140%.

Excellent washing results

Saving water with a special cascade design in ECO wash and the intermediate squeezing rollers.

The integrated roller-lifting device, easier yarn repairing, better cleaning and maintenance, less preparation time.

In Bangladesh, it is represented by Cott-tex Associates. For any query mail: khalid@cott-tex.com or call +88 01912 000428