Nanjiba Nur

Introduction

Denim is one of the most polluting industries in the fashion market. Nowadays we try to invent more environmentally friendly manufacturing technologies than the traditional ones. Despite the ecological facts, it still keeps being a rapidly growing part of the fashion market. Behind the giant denim industry, big problems are enormous quantities of second-hand trash, unsold stock, and denim waste, which has to be processed again anyway. On the other hand: the repurposing of denim waste into fashionable items is only in some cases part of the sustainability process. There are many opportunities offered to enthusiasts of denim today; advanced and organic denim, less polluting fabric dyeing and washing processes, zero water technologies, oxygen and ozone washes, recycling processes, and eco-denim projects, and so on. In this article, we put light on eco-friendly technologies for the denim industry.

Denim is one of the most polluting industries in the fashion market. Nowadays we try to invent more environmentally friendly manufacturing technologies than the traditional ones. Despite the ecological facts, it still keeps being a rapidly growing part of the fashion market. Behind the giant denim industry, big problems are enormous quantities of second-hand trash, unsold stock, and denim waste, which has to be processed again anyway. On the other hand: the repurposing of denim waste into fashionable items is only in some cases part of the sustainability process. There are many opportunities offered to enthusiasts of denim today; advanced and organic denim, less polluting fabric dyeing and washing processes, zero water technologies, oxygen and ozone washes, recycling processes, and eco-denim projects, and so on. In this article, we put light on eco-friendly technologies for the denim industry.

Denim, the Complex Supply Chain

Denim is a dynamic, featuring a field of fashion where the achievements of science and new features of lifestyle are assumed in sew styles. To understand the modern phenomenon of denim topic has to be accessed from different aspects. Again the phenomenon of denim is a complex one, with multifaceted local and global interests behind the scene, where the economic aspect makes the essence of the topic. This field of fashion is a rapidly growing business, thus continuous monitoring of the market is a must for all professionals. Denim is one of the biggest employers in the world; it’s giving work to lots of people: stakeholders in the textile, garment and fashion industry, including small and medium enterprises and large companies, designers and creative personnel of leading global fashion houses and emerging brands, actors of the retail sector (buying/selling, distribution, promotion, etc.), as well there are huge interests of machinery makers, workers and technologists of the weaving mills, and so on. There is an endless list of employees and employers interested in a supply chain of the blue industry. That’s why is important to reflect on the environmental aspects of this topic, by reflecting on some Eco-design and denim recycling projects. We can see that the world of denim became ever more socially responsible than was in the past. If drawing attention to new achievements of the science, that make this field fresh and exciting, there’s featuring a future of denim above more sustainable awareness than it was in its heroic history.

Denim is a dynamic, featuring a field of fashion where the achievements of science and new features of lifestyle are assumed in sew styles. To understand the modern phenomenon of denim topic has to be accessed from different aspects. Again the phenomenon of denim is a complex one, with multifaceted local and global interests behind the scene, where the economic aspect makes the essence of the topic. This field of fashion is a rapidly growing business, thus continuous monitoring of the market is a must for all professionals. Denim is one of the biggest employers in the world; it’s giving work to lots of people: stakeholders in the textile, garment and fashion industry, including small and medium enterprises and large companies, designers and creative personnel of leading global fashion houses and emerging brands, actors of the retail sector (buying/selling, distribution, promotion, etc.), as well there are huge interests of machinery makers, workers and technologists of the weaving mills, and so on. There is an endless list of employees and employers interested in a supply chain of the blue industry. That’s why is important to reflect on the environmental aspects of this topic, by reflecting on some Eco-design and denim recycling projects. We can see that the world of denim became ever more socially responsible than was in the past. If drawing attention to new achievements of the science, that make this field fresh and exciting, there’s featuring a future of denim above more sustainable awareness than it was in its heroic history.

Classical Technologies in Denim

Denim washing is a technology that is used to soften the raw material and give it a used look. It is done to produce effects like color fading, crinkles, seam puckering, hairiness, de-pilling or softened hand feel, etc., as well to stabilize the dimensions of the product because of the shrinkage of the fabric. Since denim constitutes the largest portion of the garments that are washed, the term ‘wash’ has come to mean the finishing of denim garments. The first one was a stone wash, invented in the late 60-s by Japanese brand Edwin and Marithé and Francois Girbaud in France – almost at the same time. Until today we don’t know who was who invented it first, but until the present day, there have been developed few more. There are different processes that can be used in various ways and may result in various effects for special products. By setting process parameters, we can change the final effect of each process. Here are the basic ones:

- Stone Washing: a most common method used to give the denim ‘old-look’, to abrade the surface of the fabric and to obtain a softer touch. The main component of the method is the pumice stone.

- Enzyme Washing: a common bio-catalytic method where the hydrolytic effect of enzymes causes the loss of surface fiber by improving the smoothness of the surface and the softness of the fabric.

- Bleach Washing (as well called acid wash or bleaching) is a cheap and quick way of finishing which is done by using a bleaching agent like sodium hypochlorite, or similar acid.

- Ice or Snow Washing is a method achieved by dry tumbling with pumice stones soaked with bleaching agents. It produces a ‘snow-like’ pattern effect on denim.

- Sandblasting is an abrading method done with sand, for obtaining a localized abrasion effect

Environmental Hazards in the Classical Technologies

Let’s be honest: denim is an awfully dirty industry! To make jeans is like making sausages. That’s why it’s usually done in undeveloped countries where the environmental regulations are not demarcated clearly. Despite the ecological facts denim still keeps being a growing part of the fashion market. Especially important is to face the aspect that denim washing is one of the most environmentally polluting technologies. Even the commonly used technologies are more environmentally friendly nowadays, if modern less polluting chemicals are used – as altogether with relevant sewage plants –, disadvantages like high energy and water consumption, multi-part production process and lots of waste support efforts of denim professionals to invent new, more environment-friendly ones. However; higher demands cause higher prices of the products, which is closely related to well-known terrible work conditions of the denim industry workers around the world. There is a clear relation between the phenomenon of fast fashion and cheap clothing and low product prices. Professionals over the world fight for maintaining of ethical rules and for moral values, maintaining principles of quality contra quantity.

Eco-friendly Technologies

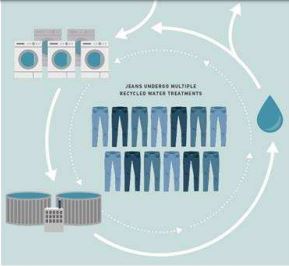

Making jeans is over more complex process than the average consumer thinks; it requires special equipment and technology, complex skills mixed with a high degree of creativity, and special knowledge. This is a very creative field of design that attracts lots of designers each season. Undying desire of the designers and the consumers supported by the multiplied global interest of denim brands, manufacturers and their give renewed meaning to the work each new season. We strive to invent more environmentally aware technologies than the traditional. The first initiative was introduced by the Levi Strauss year 2011, when the company began using Water. Until today there were many of them is offered to enthusiasts of denim: the zero-water technology, Ozone Wash, less polluting and less energy/water consuming Advanced Denim Technology and Laser Wash – together with the a less polluting fabric dyeing solutions – are over more perfect denim finishing know-hows. Their substantial advantages are:

Making jeans is over more complex process than the average consumer thinks; it requires special equipment and technology, complex skills mixed with a high degree of creativity, and special knowledge. This is a very creative field of design that attracts lots of designers each season. Undying desire of the designers and the consumers supported by the multiplied global interest of denim brands, manufacturers and their give renewed meaning to the work each new season. We strive to invent more environmentally aware technologies than the traditional. The first initiative was introduced by the Levi Strauss year 2011, when the company began using Water. Until today there were many of them is offered to enthusiasts of denim: the zero-water technology, Ozone Wash, less polluting and less energy/water consuming Advanced Denim Technology and Laser Wash – together with the a less polluting fabric dyeing solutions – are over more perfect denim finishing know-hows. Their substantial advantages are:

- Less or zero water consumption · Energy savings · Process time savings · Chemical savings · Improved quality and reduced volumes of waste · Improved tensile/tear strength of finished goods · Reduced second quality · Labor savings.

Conclusion

Though a filthy production process, denim has some outrageous fashion features that is accepted gleefully in any fashion setting. Increasing demand and endless consumer choice is a great incentive for the denim industry to opt for environmentally friendly technologies to lessen the burden on the environment. Innovations in eco-friendly technologies are seen to evolve vigorously in the recent past. It is the responsibility of the manufacturers now to adopt suitable technologies that is viable in their business setting.

References:

- Sustainable Concepts and Eco-Friendly Technologies in The Denim Industry, Edited by Csanák Book of Proceedings Icdlit (International Conference on Design And Light Industry Technologies)

- Denim innovations: How brands are cleaning up the industry, URL: https://fashionunited.uk/news/fashion/denim-innovations-how-brands-are-cleaning-up-the-industry/2021041454984

- Photo credit: Vogue, Fashion Insider