Denim is a versatile and adaptable fabric that has established itself as a mainstay in global fashion. Denim’s history is as complex and multifaceted as the blue hues that make it, having begun in the 19th century as work clothes for laborers and miners and evolving into today’s reputation as a symbol of both casual and haute couture. However, the heritage of this treasured fabric has been shadowed by its traditional dying methods, which raise serious environmental issues. The fashion industry is facing the challenge of sustainability, and environmentally friendly dyeing methods have become a vital area for innovation and change. Denim is traditionally dyed using synthetic indigo, a resource-intensive process with significant environmental implications. Conventional techniques produce a great deal of waste and pollution since they require a lot of water, energy, and chemicals. Untreated or insufficiently treated effluents damage ecosystems, endangering aquatic life and having an impact on the communities that depend on these water supplies. Furthermore, both consumers and employees are at risk for health problems when dangerous substances like formaldehyde, heavy metals, and azo dyes are used. The industry is searching for greener options that reduce environmental harm while preserving the quality and allure of denim due to the combined effects of these methods.

Eco-friendly dyeing techniques are becoming more popular as workable answers to these problems, with the goal of completely changing the denim manufacturing process. The utilization of natural colors made from plants, minerals, and other organic sources is one of the most promising strategies. These colors provide a non-toxic, biodegradable substitute that may be safely released back into the environment, in addition to reducing dependency on artificial chemicals. For example, with the advent of science, dyes derived from Indigofera plants, which were historically employed in dyeing procedures, are being reexamined to improve their colorfastness and efficiency. Adopting dyeing technologies that use less or even zero water is another creative strategy. Water use is significantly reduced by methods like foam dyeing and laser dyeing, which put dyes directly onto the fabric with the use of sophisticated technology. For instance, foam dyeing uses air bubbles to disperse dye uniformly while using less water and chemical waste. Contrarily, laser dyeing uses laser technology to etch patterns and colors onto denim, thereby doing away with the need for water and using less energy. These techniques offer financial as well as environmental advantages by streamlining production procedures and protecting valuable water resources. Developments in biotechnology are also essential to the creation of sustainable dyeing techniques. For example, enzymatic treatments provide a bio-based substitute for the harsh chemicals used in conventional dyeing. Enzymes make it easier for dyes to be fixed to fibers at lower temperatures and with less water used, making the process kinder and more environmentally friendly. Furthermore, the creation of genetically modified microbes that can produce indigo dye opens the door to more efficient and eco-friendly production techniques. These biotechnological advancements emphasize eliminating dangerous materials and advancing safer, more environmentally friendly processes, which align with the tenets of green chemistry. Making the switch to environmentally friendly dyeing methods is not without its difficulties. To achieve widespread acceptance, the fashion industry must overcome technological, economic, and logistics obstacles. The industry’s aversion to change, ensuring the scalability and affordability of sustainable technologies, and upholding uniform quality and color standards are all critical challenges that must be overcome. To drive this shift, manufacturers, designers, researchers, and politicians must work together. Essential elements of this cooperative strategy include establishing legal frameworks, offering incentives for sustainable practices, and increasing consumer demand for and understanding eco-friendly products.

Since their introduction, denim pants, also referred to as “blue jeans,” have been widely accepted by individuals of all ages, socioeconomic backgrounds, gender identities, and statuses. They are made entirely of cotton. Over time, it has evolved from being associated with cowboys to becoming a staple item of clothing for young people, adults, and everyone in between. Workwear gave way to casual wear, which was followed by upscale and practical clothing. Cellulase enzyme is primarily used by the denim washing industries, either by itself or best in conjunction with a pumice stone, to produce a soft handle and a seemingly worn appearance. Apart from satisfying the growing market demand for denim, research has been done to achieve comparable or better appearance and manufacturing conditions by implementing environmentally friendly emerging processing techniques like sandblasting, laser, plasma, and ozone. This is done to address issues related to environmental concerns associated with traditional washing. Denim has frequently been tried to be desized, but its color faded using oxygen cold plasma. Compared to an appropriate enzyme-treated material, the faded effect is more noticeable. Three different laser sources were investigated for denim processing: a Nd: YAG laser (1.064 μm and its second harmonic, 532 nm), a C.T.H.:YAG laser (2.09 μm), and a CO2 laser (10.6 μm). Out of these, the CO2 laser was determined to be the most effective and appropriate for denim processing.

Water pollution is typically the main cause of the pollution issues caused by denim wet processing. Lint, chemicals, and other things cause other minor problems with air pollution. The technique of damp processing denim has the most significant influence on air and water pollution. The denim business produces a lot of wastewater since it uses a lot of chemicals and water in its operations.

- Dyeing and Dimensioning

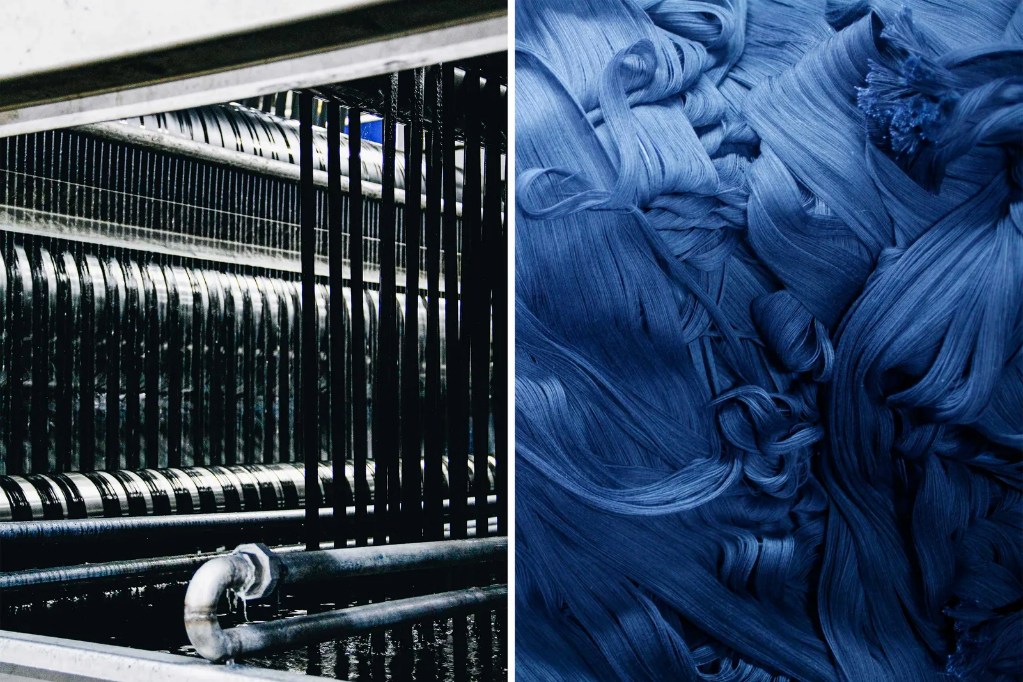

Yarn sizing is primarily used to bond the fibers to strengthen the yarn chemically. Additionally, the protective-size coating keeps the denim indigo dye from wearing off throughout the manufacturing process. Typically, sizing applies a range of 8–12%. A survey claims that the sizing procedure may be responsible for almost 50% of the pollution overall. Numerous contaminants, including dyes and compounds like sodium hydroxide and sodium hydrosulfite, are linked to the process of dying denim. Chemicals used in cleaning, equipment maintenance, and dyeing are also linked to pollution. Not every denim dye is typically fixed on the warp sheets or layer. Since 100% fixation cannot be achieved during dyeing, the unfixed dyes combine with the water bodies, causing excessive turbidity that is harmful, carcinogenic, or mutagenic to the ecosystem. Turbidity hinders light transmission, which has a negative impact on aquatic plants’ capacity to photosynthesize.

- Eco-Friendly Denim Dyeing

Most synthetic indigo is utilized in dyeing processes due to the scarcity and high demand for natural indigo. Currently, just 1% of all indigo applications are made using natural or plant-based indigo. It is not feasible to produce plant-based indigo colors on a larger scale due to the need for vast amounts of land for cultivation. Thus, aniline, another name for crude oil, is used to make synthetic indigo. Unfortunately, not all synthetic dye can be applied to the warp sheets; as a result, part of it ends up in wastewater and negatively impacts the ecology. In order to contribute to environmental protection, at least in part, a lot of organizations these days are encouraging the use of natural indigo in their businesses. Because indigo is water-insoluble, it needs a large amount of alkali (NaOH) plus a reducing agent, like sodium dithionite (Na2S2O4), to become soluble in water. The B.O.D. and other pollution metrics will rise when alkali and a reducing agent are used.

The electrochemical reduction of indigo dyes is a subject of great interest to many scientists and researchers. They have investigated the environmentally friendly synthesis of water-soluble indigo dyes using the electrochemical reduction of indigo dyes utilizing ultrasonics in an aqueous system. Elevating the pH can lead to an increase in the reduction potential, implying improved mass transfer. The process’s usage of ultrasonic aids in particle size reduction. This technology is environmentally clean and green, and it has numerous benefits over the traditional (chemical) reduction method. Among the benefits are lower costs, increased energy efficiency, and the elimination of the requirement for Na2S2O4 and NaOH. This is an innovative method for sustainable and eco-friendly indigo dyeing.

- Stones Washing

Stone cleansing frequently involves the use of pumice stones. Because of its excellent porosity, pumice is a stony, lightweight material that floats on water. It is the result of an eruption of a volcano. The process of stone washing gradually breaks the strands on the fabric’s outer layer, removes them, and exposes the warp yarn’s inner white fibers—a process known as “ring dyeing.”

- Sustainable Enzyme Washing Method

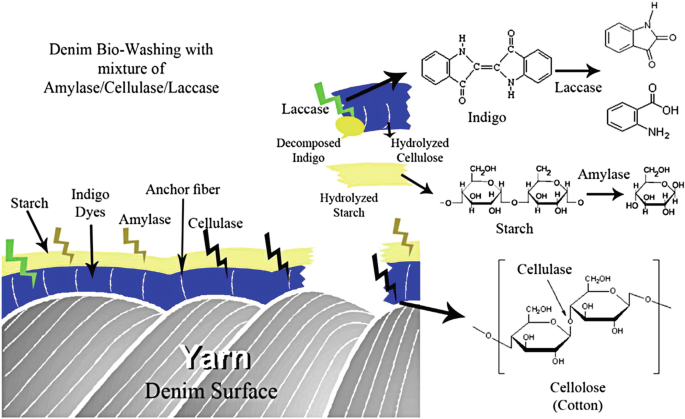

A variety of environmentally friendly enzymes have entered the denim processing industry, taking efficiency and environmental considerations into account. An enzyme is described chemically as a protein complex made up of approximately 200–250 amino acids. Even though hydrolysis is the most frequent reaction among all, enzymes can also cause oxidation, reduction, coagulation, and breakdown at the same time. Enzymes function under mild settings, speed up reactions, work only on particular substrates, are simple to manage, and are biodegradable. Enzymes are widely utilized in the preparation of denim because of their unique properties. The abrasive impact of pumice stones on the cloth used to fade the color of denim in the traditional stone washing procedure, giving the garment a worn-out look. The cellulase enzyme is employed in bio-stoning finishing to speed up the abrasive process. It does this by lowering the amount of indigo dye on the denim surface. This enzymatic technique makes treating wastewater in effluent plants easier and produces fewer pollutants.

- Sustainable Bleaching Method

Using other methods that don’t harm our environmental systems is especially crucial in light of the demand for bleached denim items. As a result, environmentally friendly options such as laser engraving, ozone bleaching, water jet fading, and enzymatic bleaching are currently in use. While none of these substitutes can match the effectiveness of sodium hypochlorite, a chemical used in bleaching products, they may be able to replace it. Numerous researchers have worked on ozone bleaching over the past few decades, but because it demands a significant financial investment, it has not been commercialized. The oxidoreductase class of enzymes, including laccases, has recently been used to bleach indigo textiles. These enzymes typically require a chemical mediator to function between them and the indigo dye; they are not autonomous. This laccase enzyme becomes oxidized in the presence of an aqueous solution, attacks the mediator, and releases free radicals as a result. The indigo is attacked by free radicals, which then cause it to change into oxidized compounds.

Conclusion

To sum up, “Denim’s Deep Dive: Considering Eco-Friendly Dyeing Processes from the Point of View” emphasizes how important it is for the denim business to adopt sustainable practices, especially when it comes to dying procedures. Conventional dyeing techniques use a lot of water, produce a lot of chemical effluent, and need a lot of energy. Promising ways to lessen these problems include investigating environmentally friendly substitutes, including closed-loop systems, plant-based dyes, and waterless dyeing processes. The denim industry can greatly reduce its ecological impact, meet the growing demand from consumers for sustainability, and open the door for a more ecologically conscious future by implementing these creative solutions. This shift is essential to the industry’s long-term sustainability and ethical commitment since it not only improves brand reputation and complies with regulations but also helps the environment and the environment.

References:

- https://www.researchgate.net/publication/318033900_Environmentally_friendly_denim_processing_using_water-free_technologies

- https://www.researchgate.net/publication/318033899_Environmental_impacts_of_denim

- https://www.premierevision.com/en/magazine/know-how-denim/?

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9909807/

- https://www.ellenmacarthurfoundation.org/fashion-and-the-circular-economy-deep-dive

- https://www.intechopen.com/chapters/41411

- https://www.indotexexports.com/blog/denim-fabric-innovations-exploring-the-future-of-sustainable-dyeing-techniques/