Soma Parven

Currently, Bangladesh is the world’s top denim exporter. But the production of so much denim is not damaging the environment!!! Textile factories are among the most significant industrial water consumers: typically require 0.2-0.5m3 of water to produce 1 kg of the finished product. Denim production uses some textile raw materials which are harmful to the environment. Because textile wet-processing industries such as dyeing, bleaching, printing, finishing, and washing processes use many toxic chemicals and require pure, clean water. In this article, we learn how to use chemicals and effluent treatment in denim processing to reduce environmental pollution and some advances in effluent treatment.

Effluent Treatment Plant (ETP)

An Effluent Treatment Plant is a type of wastewater treatment system specially designed to purify and reuse industrial wastewater. It aims to keep the environment free of pollution from the harmful effects caused by effluent. The textile industry is the most water-consuming and generates the most waste, which is detrimental to the natural environment, polluting the surrounding water and soil. To get rid of this problem, an ETP plays an essential role in protecting the domain from the harmful effects of wastewater in the textile industry.

Effluent Treatment Methods

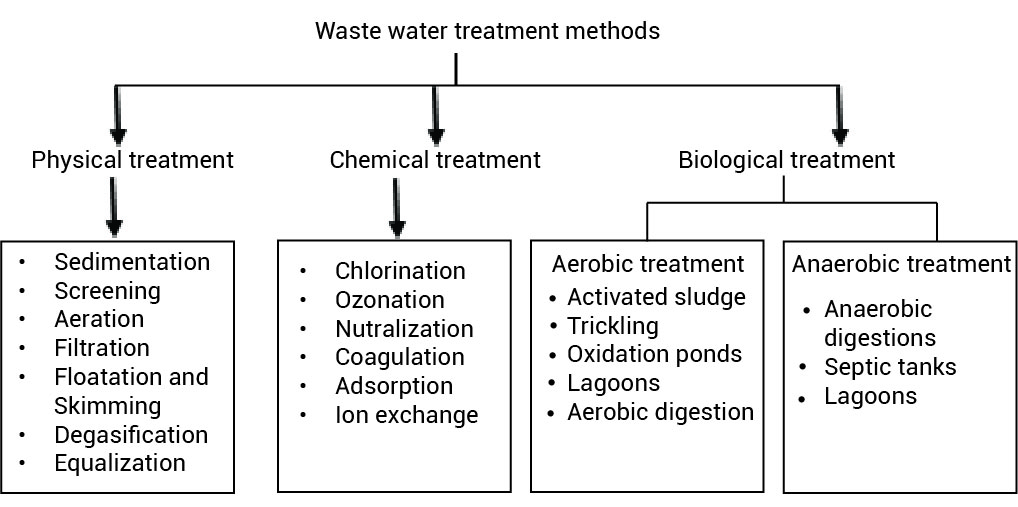

Usually a waste treatment plant (ETP) for a textile industry consists of primary, secondary and tertiary treatment to ensure optimum performance. Physical, chemical and biological methods used to remove contaminants from wastewater. General classification of various waste treatment methods used in textile industry described below:

Physical Treatment

Physical treatment is considered the primary waste treatment and represents the first stage of wastewater treatment. These treatments mostly remove suspended, precipitated or flocculated solid particles.

- Sedimentation (clarification): This process removes suspended solids from wastewater by gravity.

- Screening: This process removes floating materials like paper and wood from wastewater with the help of mechanical bar screens.

- Aeration: This process is usually applied to water bodies that experience pollution. A surface agitation process can also achieve aeration with a spray-like device which allows wastewater to be exchanged with oxygen at the surface and noxious gases such as carbon dioxide and methane.

- Filtration: Removes residual suspended particles and volatile sludge from wastewater.

- Flotation and skimming. In wastewater treatment, flotation primarily removes light-suspended solids (oil, grease, etc.).

Chemical Treatment

Chemical processes used in wastewater treatment form change in some chemical reactions. Chemical methods are combined and used with physical unit operations and biological processes.

- Chlorination: This treatment method sterilizes or destroys wastewater pathogens and prevents the water from decomposing.

- Ozonation: Ozonation introduces an unstable molecule to wastewater and releases an oxygen atom in water molecules, converting it into a powerful oxidizing agent.

- Coagulation: The main principle of coagulation treatment is to conduct an electric charge or flow ions and colloids (organic and inorganic) into the wastewater stream. In this process, the colloids are strengthened by adding ions with opposite charges.

- Adsorption: Through this method, pollutants in the wastewater are adsorbed and removed on the surface of the porous material or filter.

Biological Treatment

Biological unit processes convert finely divided and dissolved organic matter in wastewater into flocculent disposable organic and inorganic solids.

- Aerobic: Under aerobic (O2) conditions, bacteria rapidly consume organic matter and convert it to CO

- Anaerobic: This is a bacterial process for domestic sewage in septic tanks. Which typically retains sewage for 1 to 2 days, reducing biological oxygen demand (BOD) by about 35%-40%.

Effluent Analysis in a Denim Processing Industry

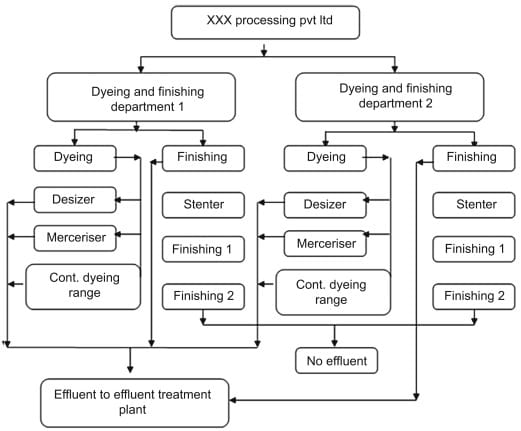

In the dyeing and finishing department, the developed fabrics are mercerized, desized, top dyed with the help of a continuous dyeing range (CDR), and finished with a soft chemical. The process flow of the dyeing and finishing department of a company image is as follows:

In this work, effluents generated from the following processing machines are analyzed for their pollution content:

- Desizer

- Mercerized

- Continuous dyeing range

- finishing machines

All the above process have discussed in below:

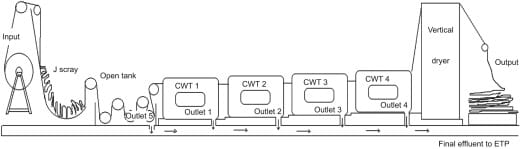

Desizing: After weaving, the sizes must be removed from the fabric. Three methods are often used in textiles processing acid, enzyme, and oxidative desizing. Sizing ingredients such as starch in fabric hinders processes like dyeing, printing, and finishing. That’s why starch is removed before dyeing or printing. Starch is removed or converted into simple water-soluble products by hydrolysis or oxidation. After it is put in, the fabric is passed into an open tank and a steamer tank, through which it is continuously washed with steam and water. After the steamer, the fabric passes into the Closed Washer Tank (CWT) 1 and then passes through CWT 2 and CWT 3. Hence the fabric is washed at all stages by CWT 4. After that, the material passes through a vertical drying range and the output is removed. Effluent from washer tanks 1-4 and open tanks the chemicals are discharged to a common outlet, which is piped to an ETP, as shown in the figure:

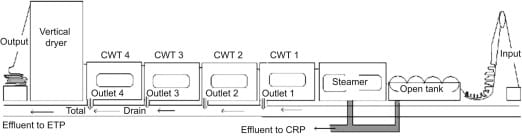

Mercerization: Basically, mercerization is carried out by treating the cotton material with a strong sodium hydroxide solution to improve dye strength, yarn strength, and smoothness, and after 1-3 minutes, wash off the caustic and hold the material under agitation. Effluents from the stabilizer and the open caustic tank go separately and are treated in a caustic recovery plant (CRP) to recover 99.99% sodium hydroxide. Fabric moves to CWT 1 after the stabilizer tank. Here the fabric is washed 90°C and passed through a set of squeezing rollers with a 2-3 bar nip pressure. From this the fabric then passes through CWT 2 and CWT 3. Due to caustic impregnation, the fabric will remain alkaline even after three washes. So, to neutralize the fabric in CWT 4. After neutralization, the material goes over the vertical drying cylinder and finally to the plaiter before the output. Here the waste from washer tanks 1-5 is discharged to the standard outlet, which are piped to the ETP, as shown in Figure:

Continuous Dyeing Range (CDR): There are generally three processes involved in CDR: caustisizing, overdyeing and desizing. Caustisizing is a process similar to mercerization. Here the fabric is treated with a caustic solution. CDR machines consist of a chemical tank and a steam stabilizer tank. After that it has a continuous washing range from tanks 1-7. Finally it has three vertical drying range. Effluent samples were collected from common outlets, which was piped into the ETP.

Finishing: Finishing is the last stage of textile fabric production. Finishes can be achieved by chemicals that change the aesthetics of the fabric or physical properties, texture or surface properties can be changed by physically manipulating the fabric with mechanical devices.

Conclusion: Recent awareness of ETP requirements should be conducted constructively. The novel methods discussed can be applied to removing various dyes from industrial effluents. As a result, environmental pollution will be reduced, water consumption will also be diminished, and society will develop sustainably. Government should come forward to facilitate the setting up of ETPs through technical guidance and financing. Through proper monitoring by the government and various private sectors, a healthy, beautiful and sustainable environment can be ensured.

References: