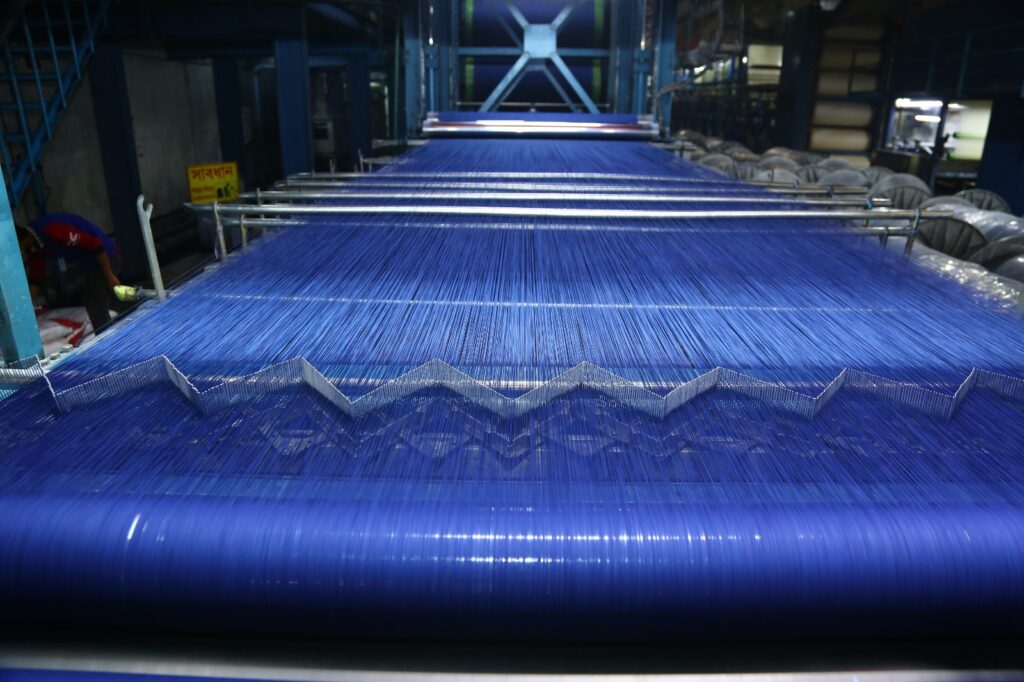

Argon Denims Ltd., a leading denim manufacturer, produces 20 million yards annually with advanced facilities with Slasher dyeing, weaving-Picanol airjet looms, Mercerizing, Sanforising, Over-dyeing, Coating, and Fabric Inspection with Shrink wrap Packing.

Argon Denims partners with top brands like H&M, Inditex, Gina Tricot, Group Dynamite, NEXT, Mango, M&S, Zalando, YM Inc, and several other renowned buyers, showcasing its commitment to quality, sustainability, and innovation.

Integrated software streamlines production, finance, HR, and purchasing, ensuring real-time tracking. The company prioritizes social sustainability through fair wages, labour law compliance, and a safe work environment. Employee welfare and continuous improvement are central to its culture.

A 4.2 lakh-litre water capacity tank is installed, accompanied by a Fire and Safety Control Building. The entire factory is equipped with over 700 advanced detection systems, including smoke detectors, heat detectors, light beam sensors, and aspiration detection systems, ensuring comprehensive fire detection and safety coverage.

Efficient warehouses ensure optimal fabric and yarn storage with accurate inventory tracking system, while chemical storage adheres to stringent safety and environmental standards.

High Standard of Quality and Sustainable Product Development

Argon Denims maintains stringent quality parameters. The company’s certified quality laboratory is equipped with advanced testing equipment and operated by highly skilled and certified professionals.

Product development is at the core of Argon Denims’ success. The company continually pushes the boundaries of innovation, creating trend-setting, high-performance denim fabrics that meet the evolving demands of the global market.

Argon Denims leads in sustainable product development, incorporating eco-friendly fibers such as organic cotton, post-industrial waste (PIW), post-consumer waste (PCW), recycled polyester, and renewable materials like bamboo and banana fibers. These initiatives underscore the company’s commitment to economic sustainability and reducing its carbon footprint.

Energy and Renewable Approach

Argon Denims operates a captive power plant powered by gas generators, ensuring a reliable and sustainable energy supply. The company has integrated energy-saving technologies, including boiler economizers, caustic recovery plants, and condensate recovery systems, significantly reducing its energy footprint.

Argon Denims is committed to expanding its energy-saving initiatives with several future projects in the pipeline. These include the installation of exhaust gas boiler, stenter heat recovery system, and hot water chillers, all designed to maximize energy efficiency. Additionally, the company plans to expand its solar power capacity to further reduce reliance on non-renewable energy sources.

Water Management

The textile industry uses about 10% of global water, risking depletion of resources. Argon Denims has prioritized water conservation, cutting consumption by 48% in five years through innovative processes and eco-friendly dyes. The company reuses condensate and cooling water and aims for 100% recycled water in production.

Argon Denims sends ETP sludge to cement factories for co-processing, drying it before disposal to Lafarge Holcim, as approved by the Bangladesh Government. The company plans to adopt Zero Liquid Discharge (ZLD) systems to further minimize environmental impact and currently operates MBR advanced effluent treatment plant (ETP). ZDHC wastewater tests are conducted through third-party audits, and the Department of Environment (DOE) of Bangladesh regularly monitors treated water quality. Any deviations trigger immediate corrective measures with root cause analyses uploaded to the ZDHC gateway. These initiatives reflect Argon Denims’ commitment to sustainable water and waste management.

Sustainable Dyeing and Finishing Processes with ZDHC.

With a strong focus on sustainability, Argon Denims employs innovative dyeing techniques such as ECO RICH Dyeing and Nature Conscious Dyeing (NCD), OMOD sulphur overdyeing process. These processes are having validation reports from BUREAU VERITAS.

Argon Denims also utilizes sustainable finishing processes like Classic Balance/Regular Finish, Vertical Reflux/Eco weft finish, Horizontal Drift/Eco warp and Eco Texture /STR finish, which minimize the consumption of steam, water, and electricity. New Eco Save concept of sanforising the fabric reduced energy consumption by 75% in low weight fabric.

The company continues to adopt innovative chemical management practices, ensuring all processes align with global sustainability standards.

Environmental Sustainability Goals

Argon Denims also utilizes renewable energy options, including solar power via Power Purchase Agreements (PPAs) and Renewable Energy Certificates (RECs), to further its sustainability goals.

The adoption of hot water chillers, biomass boilers, and energy-efficient machinery is projected with a target of achieving a 56% reduction in greenhouse gas (GHG) emissions from the 2022 baseline. A 30% water reduction and 100% sustainable chemical uses are targeted by 2030 from the 2022 baseline.

Adopted Sustainable Programs and Audits

Argon Denims is dedicated to upholding the highest sustainability standards through globally recognized programs and audits. It holds certifications such as GOTS, GRS, RCS, and OCS, managed by GSCS, and OEKOTEX certification from Honestein. Argon Denims undergoes Higg FSLM/FEM, SMETA audits conducted by Intertek and BV. Green Bud BD is doing environmental assessments of company.

The company participates in the GREEN TO WEAR program in partnership with Intertek and Inditex, while managing environmental improvement programs and chemical inventories with BV. The effluent treatment plant is regularly assessed by TUV Rheinland and Bluwin Limited. As a ZDHC Supplier to Zero, Argon Denims’ wastewater management is validated through ZDHC’s Clear Stream Report, in-check program-BVE3, and Higg FEM audits by Bureau Veritas (BV). These initiatives underscore Argon Denims’ commitment to environmental stewardship and continuous improvement.

Commitment to Continuous Improvement

Argon Denims Limited is deeply dedicated to sustainability and the adoption of renewable clean energy. The company consistently seeks to enhance its processes by integrating cutting-edge technologies and innovative concepts, aiming to elevate both environmental and overall sustainability standards. Transparency is a cornerstone of Argon Denims’ operations, encompassing all aspects from production and finance to strict adherence to government regulations. This commitment is firmly rooted in the principles established by the company’s Board.

The proactive approach towards innovation and accountability underscores Argon Denims’ leadership in sustainable denim manufacturing and its unwavering pursuit of environmental stewardship.

Conclusion

Argon Denims Ltd. exemplifies how advanced technology, sustainable practices, and social responsibility can harmoniously drive industrial success. Through its innovative approach to denim production and steadfast commitment to sustainability. The company’s vision for the future is clear: to lead the global denim market by championing innovation, sustainability, and excellence across all aspects of its operations.