Hydros-D: A Stable, Safer & Superior Hydrosulphite for Indigo Dyeing process from the stable of Silox India Private Limited (A group company of Silox.S.A, Belgium). The product meets all relevant International Standards of sustainability such as EcoPasport, GOTS, ZDHC certifications.

Hydros-D: A Stable, Safer & Superior Hydrosulphite for Indigo Dyeing process from the stable of Silox India Private Limited (A group company of Silox.S.A, Belgium). The product meets all relevant International Standards of sustainability such as EcoPasport, GOTS, ZDHC certifications.

Silox India’s manufacturing locations are bestowed with OHSAS 18001, ISO 9001 and ISO 14001 certification from TÜV Nord, Germany. The company is also a “Responsible Care” logo-holder company. Our QA laboratory is accredited by NABL, and R&D is approved by the Department of Scientific & Industrial Research (DSIR), Ministry of Science and Technology, Government of India

Silox S.A, Belgium has manufacturing plants in Europe, North America and India and is a major producer of Sodium Hydrosulphite in the world. Silox India Private Limited, is the largest manufacturer of Sodium Hydrosulphite in Asia, outside of China.

Silox Inda Private Limited, has a strong global presence through exports to more than 65 countries spread across six continents of the world.

Hydros D is one of the flagship products of the company manufactured through the Most preferred Zinc process offering various inherent properties in product, which differentiate itself from traditional Sodium Hydrosulphite. The product is developed through Silox India’s rich and wide experience in the application industry and is very efficient, stable and safer product for VAT/Indigo Dyeing applications.

Some of the salient features of Hydros D,

- The highly Crystalline product offers better stability.

- Low powder content in the product offers lower Dusting while usage hence better handling, smooth and continuous feeding in dyebath without chocking risks, better shop floor experience (less smell while usage). It also offers lower & health hazards through the lower dusting of Sodium Hydrosulphite on shopfloor.

- Longer shelf life as compared to Sodium formate process products.

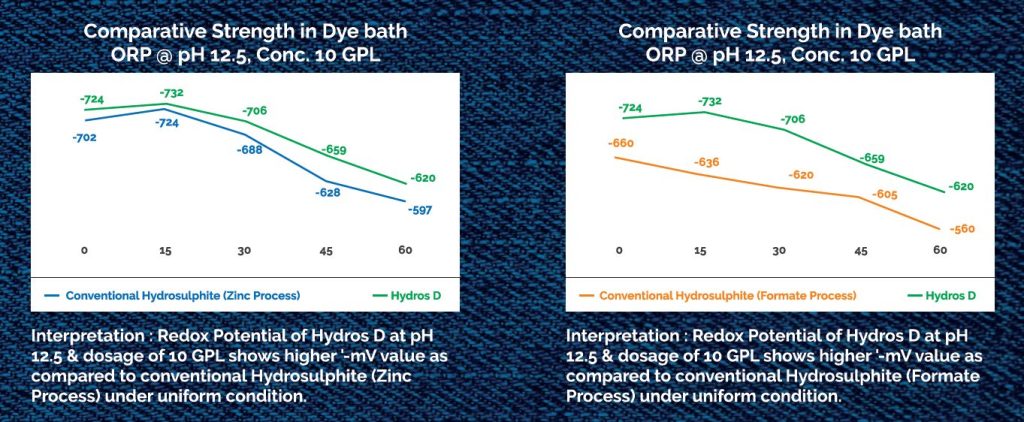

- Gives Alkaline reaction in dyebath offering Higher Free ‘Dithiionite Ion’ in dyebath at all times when compared to Sodium Formate route Sodium Hydrosulfite.

- Lowers dosage frequency to maintain pH, Redox of dye bath thereby offers lower consumption and consistent shade management.

- Less monitoring of the dyeing process throughout the cycle.

- Lower dosage for the same targeted shade lowers Salt Generation in the effluent.

- Preferred by the most Indigo (Powder and Liquid) suppliers.

Presence in Bangladesh

Hydros-D is marketed by Dysin Group in the Bangladesh market and DYSIN is the sole agent for Silox India Products including Hydros-D. Team Denim Focus talked with Mr. Abdullah Al Manuhud, DGM & Head- Garments Washing & Head, Dysin Group regarding different features and Specialities of the products.

Mr.Mahmud shared the experience of key Denim Customers using Hydros D in Bangladesh

Unique Feature of Hydros-D: Elevating Textile Dyeing Precision

Hydros-D boasts a distinctive feature that sets it apart from the crowd: it ensures not only enhanced leuco GPL stability within the dye bath but also elevates the reactivity of indigo. This unique combination results in deeper, more vibrant fabric shades while minimizing variations in color intensity.

Setting Hydros-D Apart: Cost-Efficiency Through Stability

In a competitive market, Hydros-D stands out by delivering cost-efficiency. How? By significantly increasing the stability of the dye bath, it reduces the need for frequent additional dosing of Hydrosulphite and Caustic soda. This reduction translates to tangible cost savings for manufacturers, making Hydros-D

Customer Feedback: A Resounding Success Story

Our journey with Hydros-D has been marked by resounding success, particularly in Bangladesh, a hub of denim fabric production. End-users have consistently reported outstanding results. They confirm achieving a RedOx potential ranging from -740 to -750 mV, a critical factor ensuring uniform and precise indigo dyeing in denim factories. Furthermore, users have lauded the low dusting characteristics and minimal fire hazard risks during storage. Hydros-D has earned certification as a highly stabilized Sodium Hydrosulphite, ensuring controlled decomposition at ambient temperatures during the indigo dyeing process.

Dedicated Client Support: Your Success is Our Priority

At Hydros-D, client satisfaction reigns supreme. Our commitment to delivering excellence extends beyond the product itself. Our highly skilled technical team from DYSIN is poised to offer comprehensive after-sales services and expert assistance with any technical challenges that may arise. Additionally, the responsive technical team from Silox is just a call away, ready to address any queries promptly. Your success is our goal, and we are here to support you every step of the way.

In summary, Hydros-D’s unique ability to enhance dye bath stability and reactivity sets it apart in the textile industry. Its cost-efficiency through reduced dosing requirements has garnered high praise from satisfied customers, particularly in the denim fabric sector in Bangladesh. With a dedicated and responsive support team, Hydros-D ensures that your textile dyeing processes are not just efficient but also backed by constant assistance, making it the optimal choice for manufacturers seeking excellence in their denim dyeing operations.

For further queries mail: mahmud@dysin.com, +8801730-338760