Kazi Raju, Sourcing / Denim developer, BESTSELLER

For over a decade, Bangladesh’s denim progress has been defined by wet process innovations from ETP efficiency and water reduction technologies to chemical compliance, ozone systems, e-flow applications, and sustainability certifications. These achievements have undoubtedly strengthened our credibility as a global sourcing destination. However, as the international market evolves and competition intensifies, it is becoming increasingly clear that wet process excellence alone is no longer enough to differentiate Bangladesh. The global denim conversation is shifting, and so must we.

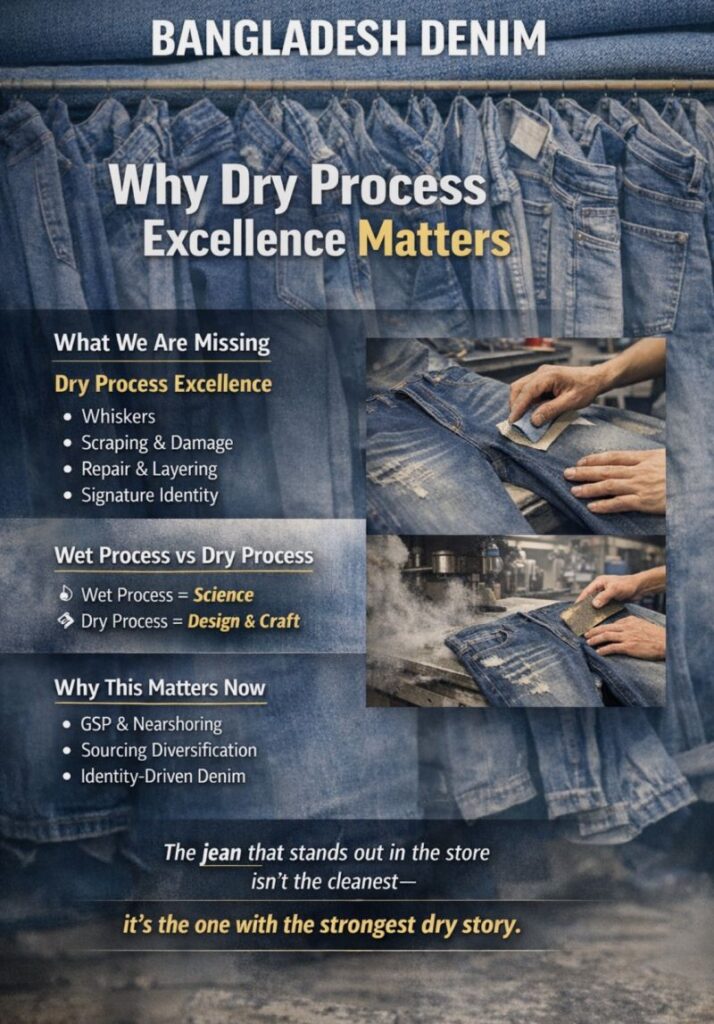

Despite having one of the strongest washing industries in the world, Bangladesh continues to face a gap in the area that visually defines premium denim the dry process. When comparing our overall aesthetic output with competitor countries, one recurring challenge stands out: our dry process creativity, execution, and identity often fall behind international standards. Areas such as whisker flow, geometry, and natural mapping still lack consistency. Scraping depth, muscle-line balance, tagging accuracy, layered texturing, damage and repair artistry, and signature pattern identity are often approached as routine technical steps instead of design-driven craftsmanship. A pair of jeans becomes truly brand-worthy not because the wet wash is clean or compliant, but because the dry process storytelling gives it character, emotion, and individuality. In other words, wet process is science but dry process is art and this artistic identity is where Bangladesh must focus next.

This need becomes even more critical when viewed against current global sourcing shifts. Changes in GSP facilities are increasing price sensitivity, while nearshoring and reshoring models are pushing retailers to demand higher aesthetic value at shorter lead times. European buyers are diversifying sourcing destinations, and brands are prioritizing denim with identity-driven finishes rather than generic commercial washes. As a result, technologies like water reduction, ozone systems, and sustainable chemical processes are no longer unique selling points but expected basics. Today, differentiation is no longer about having sustainability machines; it is about having design identity. The factories that win the next decade will not be the ones that simply comply better, but the ones that create better.

To move forward, Bangladesh must begin investing in dry process creativity rather than relying solely on technical operators. The industry needs trained denim finishers who understand whisker geometry, natural body movement, and visual balance. Laser technology must be blended with manual artistry, because originality cannot be programmed by software alone. Every factory should work towards developing a dry process library a signature archive of finishes, whiskers, textures, and damage identities that represent the factory’s character. Teams must be trained on global trend mapping and the logic behind design aesthetics, not just the mechanical execution. Finally, establishing a recognized dry process QC standard is essential, because while wet process QC is common across the industry, dry process quality control is still largely overlooked.

Bangladesh already leads the world in capacity, compliance, and sustainable washing, but leadership in the next era will be defined by creativity, aesthetic identity, and design differentiation. The jeans that win on a retail wall are not the ones with the cleanest enzyme performance but the ones that tell a story through whiskers, textures, aging, character, and hand-crafted personality. Bangladesh has mastered the fundamentals; now the country must master the finish. To secure our competitive edge in the coming decade, prioritizing dry process excellence is not just an opportunity it is a necessity.